2025-07-25

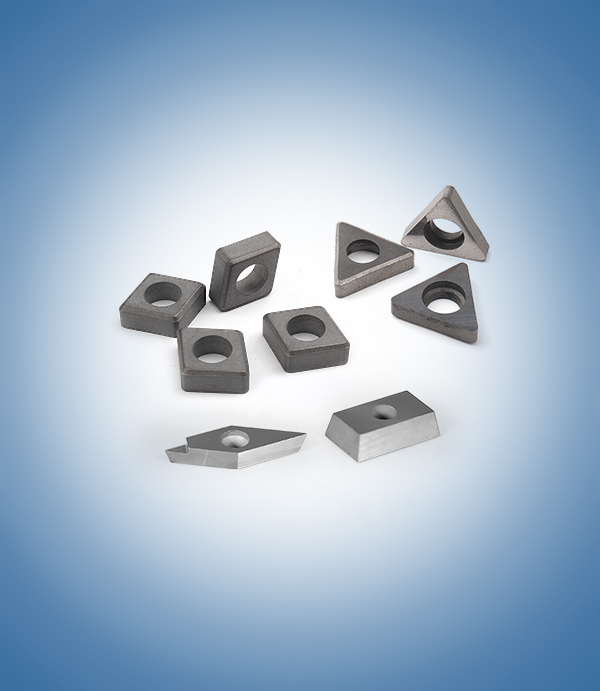

When cutting tough materials like stone or metal, precision and durability are critical. Carbide welding blades and cut stone blades are high-performance blades designed to meet the demands of demanding cutting applications. Customizing these blades to specific requirements can significantly increase efficiency, reduce maintenance, and extend the life of the blade and cutting equipment.

Custom Carbide Blades for Optimal Performance

Not all cutting tasks are the same, and the key to getting the optimal results is choosing the right blade.We can manufacture custom carbide welding blades and stone cutting blades to your exact specifications, ensuring they meet the performance needs of your specific application. By adjusting factors such as blade size, tooth shape, and coating, we can create a blade that cuts efficiently, lasts long, and performs reliably.

Known for their high strength and wear resistance, carbide welding blades are ideal for cutting hard and abrasive materials. By choosing a custom solution, businesses can optimize the life and performance of the blade, reducing downtime and maintenance costs.

Material Selection and Manufacturing Process

The materials used to manufacture carbide welding and stone cutting blades are critical to their performance. Tungsten carbide is a worthy material to consider for blades in demanding applications due to its superior hardness and heat resistance. Custom blades made from high-quality carbide will stay sharper longer, even in relatively harsh cutting environments.

The manufacturing process for these blades involves precision engineering, ensuring that each blade meets the exact specifications required for optimal performance. Customization options, such as adjusting the hardness or geometry of the blade, can further improve cutting accuracy and reduce wear, ensuring a smooth and efficient cutting process.

Versatility for a Variety of Industries

Carbide welded cutting stone saw blades are widely used in industries such as construction, manufacturing, mining, and stone processing. These saw blades are suitable for processing a variety of materials, from hard stone such as granite to metals used in heavy machinery. The ability to customize saw blades for specific materials and applications makes the cutting process more efficient and economical.

For industries that process special materials such as optical fiber or concrete, custom carbide saw blades can provide the durability and precision required for these demanding tasks. The versatility of these saw blades makes them suitable for different industries, helping to increase productivity and reduce operating costs.

Extended saw blade life and reduced operating costs

Custom carbide saw blades are an investment in performance and cost-effectiveness. The durability of carbide materials means that saw blades generally last longer, reducing the need for frequent replacement. This not only helps to reduce operating costs, but also reduces downtime, allowing businesses to maintain higher productivity levels.

Custom blades are designed to increase cutting speed and precision, so that each job is completed more efficiently. By optimizing the blade geometry and material composition, businesses can achieve more consistent cuts, which reduces the burden on the blade and the machine used.

Quality & Consistency

Quality control plays an important role in the manufacturing process of custom carbide welding and stone cutting blades. Regular testing helps ensure that each blade meets the required standards and performs as expected. By focusing on quality throughout the production process, businesses can be confident that the products they receive will meet their long-term needs and support operational efficiency.

Custom blades are designed with the end user in mind, helping to ensure that each blade is suitable for its intended purpose. This tailored approach means that businesses are more likely to get value from their investment in carbide blades.

Custom carbide welding and stone cutting blades provide an effective solution for industries that require high-performance cutting tools. By providing blades that meet specific needs, businesses can improve cutting efficiency, reduce downtime, and increase productivity. Whether you are cutting stone, metal, or other tough materials, custom blades provide the precision and durability needed to get the job done.