2025-10-31

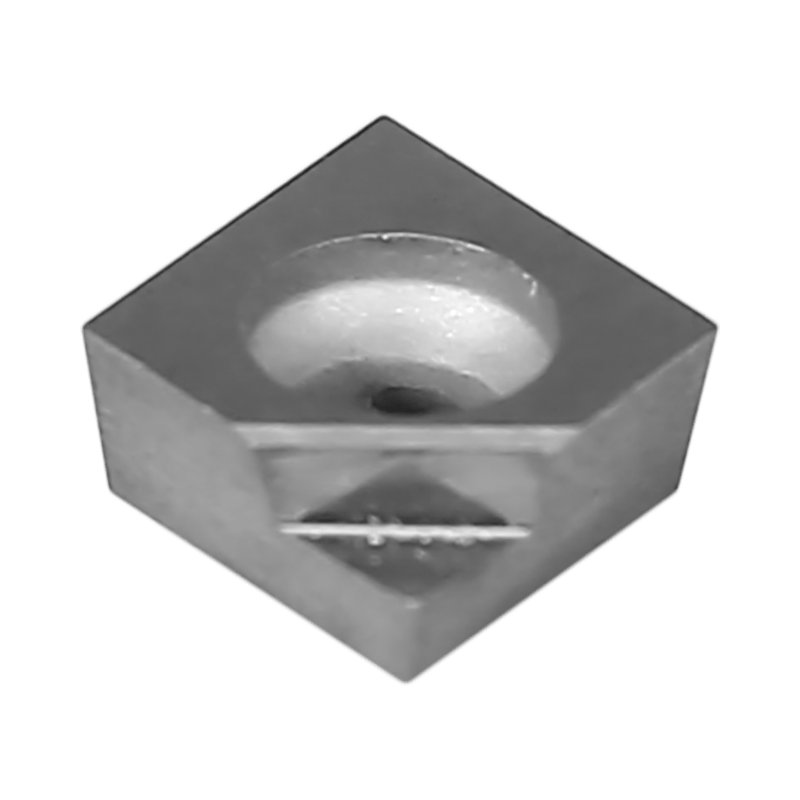

The design of an insert, particularly its geometry, has a direct influence on machining outcomes, from material removal rates to surface finish quality. The Generic Triangle Shape Carbide Cutter Insert Shim demonstrates how insert geometry brings versatility and precision into modern manufacturing processes, while welded blades continue to offer value in specific high-load conditions.

The geometry of an indexable insert determines how the cutting edge interacts with the material. Triangle-shaped inserts provide multiple usable edges, which can be rotated when wear occurs, maintaining consistent cutting conditions. This ensures more stable chip formation and controlled cutting forces. By contrast, a carbide welding blade has a single edge, and once it becomes worn, the blade either requires regrinding or replacement. This limitation can reduce efficiency in environments where frequent tool changes are needed. Inserts, with their optimized edge design, allow for smoother transitions between operations and help maintain cutting consistency across longer production runs.

Well-designed geometries, such as positive rake angles or optimized chip breakers, help reduce vibration and stabilize the cutting process. The Generic Triangle Shape Carbide Cutter Insert Shim supports applications like threading and grooving where dimensional accuracy and surface finish are important. Welding blades, while strong and durable, often deliver less flexibility in geometry adjustment. This makes them less adaptable when surface finish or precision tolerances are critical across different materials.

Manufacturing rarely involves a single type of material. Steel, cast iron, and non-ferrous alloys each react differently to cutting forces. Indexable inserts are available in multiple geometries that can be chosen to match the requirements of these materials. For example, sharper edges may be selected for softer alloys, while stronger geometries are chosen for harder materials. The welding blade, being fixed in shape, lacks this level of adaptability. It may still excel in certain heavy-duty conditions, but it does not offer the same flexibility when production lines handle diverse materials within short time frames.

The ability to rotate an insert edge extends its overall usability. Each edge provides a fresh cutting surface, which reduces downtime and lowers the need for full tool replacement. This approach also maintains consistent tool performance across the production cycle. A carbide welding blade, however, requires more intensive maintenance. When its edge becomes dull, it either undergoes regrinding or complete replacement, both of which can increase downtime. For operators balancing efficiency with tool life, insert geometries present an advantage by distributing wear across multiple cutting edges.

Cutting conditions such as feed rate, depth of cut, and spindle speed influence tool performance. Indexable inserts are designed with geometries that adapt to these conditions, providing stability in both roughing and finishing operations. For example, chip breaker designs incorporated into inserts help manage heat and prevent chip clogging, which enhances process stability. Welding blades, while highly rigid, may be less responsive to these variable conditions because their single-edge geometry cannot be modified for different operational needs. As a result, inserts often bring more consistent performance in settings where production demands change frequently.

The choice between an insert and a welded blade often comes down to the balance between flexibility and toughness. Inserts are designed to enhance productivity by supporting quick edge changes and multiple machining tasks with one geometry. This is valuable in mixed-production environments. On the other hand, carbide welding blades are often chosen for operations that demand higher rigidity, especially in heavy interrupted cuts where tool stability against impact is a greater priority than versatility. This balance highlights that both solutions have roles to play, depending on the exact nature of the production line.

The Generic Triangle Shape Carbide Cutter Insert Shim provides a clear example of how insert geometry directly influences machining results. With its triangular design, the insert supports milling, threading, and grooving operations without requiring extensive tool changeovers. Each cutting edge can be indexed into use, reducing downtime and ensuring dimensional consistency across a variety of components. For operators aiming to maintain steady workflow with fewer interruptions, this insert geometry proves especially practical in workshops where flexibility and accuracy are equally important.