2025-11-21

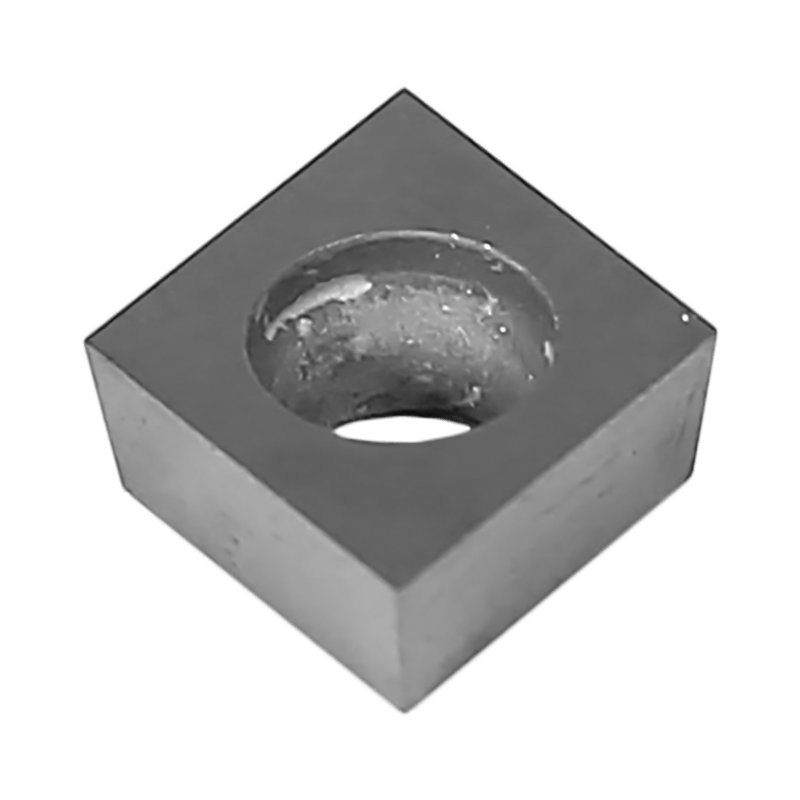

Machining efficiency and surface quality depend heavily on tool material, cutting conditions, and workpiece properties. Among modern cutting tools, Carbide Brazed Tips and Carbide Tips have earned wide application because they handle tough materials under demanding environments. These cutting inserts, combining tungsten carbide hardness with a strong bonding structure, allow manufacturers to work efficiently with different metals and alloys while maintaining precision.

Carbide Brazed Tips are highly suitable for hard and abrasive materials such as cast iron, tool steel, and high-strength alloys. These materials are often challenging to machine using conventional high-speed steel tools, as the edges dull rapidly under friction. The hardness of tungsten carbide enables it to retain a sharp cutting edge even after prolonged contact with abrasive surfaces. This property makes it effective for continuous operations where surface consistency and dimensional accuracy are essential.

For gray and ductile cast irons, Carbide Tips offer consistent chip formation and control. The strong cutting edge reduces the chance of edge chipping, while the brazed joint absorbs vibration that often occurs during rough turning. This makes them practical for applications requiring both strength and precision, such as machining cylinder blocks, housings, and heavy cast components.

Machining alloy and carbon steels is another area where Carbide Brazed Tips perform well. Steels often present varying hardness due to heat treatment or alloying elements, which can cause uneven tool wear. The combination of tungsten carbide and cobalt binder gives Carbide Tips the toughness needed to withstand impact loads and edge wear in such conditions. Operators benefit from longer tool life and fewer adjustments, especially during high-volume production runs.

When turning carbon steels or medium-hard alloys, carbide maintains sharpness and dimensional control over long cutting intervals. The tool’s rigidity ensures stable chip removal and improved surface finish without excessive tool pressure.

Stainless steel and heat-resistant alloys, such as Inconel and titanium-based materials, pose significant machining challenges due to their toughness and tendency to generate heat. Carbide Brazed Tips are well adapted to these materials because of their high temperature stability and resistance to built-up edges. The carbide structure prevents softening at elevated temperatures, maintaining cutting integrity during prolonged operations.

The brazed construction also provides strength at the tool-tip interface, helping resist mechanical fatigue from high cutting forces. When machining stainless steel components such as valves, pump parts, or fittings, the consistent sharpness of Carbide Tips ensures uniform surface finishes and reduced rework. Proper coolant flow and optimized feed rates can further extend the service life of the tool and enhance productivity.

Non-ferrous materials like aluminum, brass, copper, and bronze also benefit from carbide machining, though for different reasons. These softer metals tend to stick to cutting edges, forming built-up layers that affect surface quality. Carbide Tips reduce adhesion due to their smooth surface and low friction properties. This ensures cleaner cuts, less tool loading, and smoother surface finishes.

Machining hardened materials or sintered metals requires tools capable of cutting through dense and abrasive surfaces. Carbide Tips, particularly those with finer grain carbides, are effective in these scenarios. They provide the necessary compressive strength to cut through hard coatings or heat-treated surfaces without rapid edge deterioration. Brazed carbide tools are commonly employed for finishing hardened shafts, gears, and wear-resistant components, where maintaining dimensional accuracy is critical.

This advantage is due to the inherent rigidity and heat resistance of carbide, which allows it to handle elevated temperatures and strong cutting forces without losing form. For industries dealing with reconditioned parts or post-heat-treatment machining, Carbide Brazed Tips offer consistent results with less risk of tool fracture.

Though primarily used for metalworking, Carbide Tips are also valuable in cutting non-metallic materials like wood, reinforced composites, and plastics. Their sharp edges and smooth cutting action reduce the risk of burning or chipping during high-speed operations. Carbide’s hardness ensures clean cuts and extended edge life even when working with abrasive composites that would quickly wear down conventional steel tools.