2026-02-06

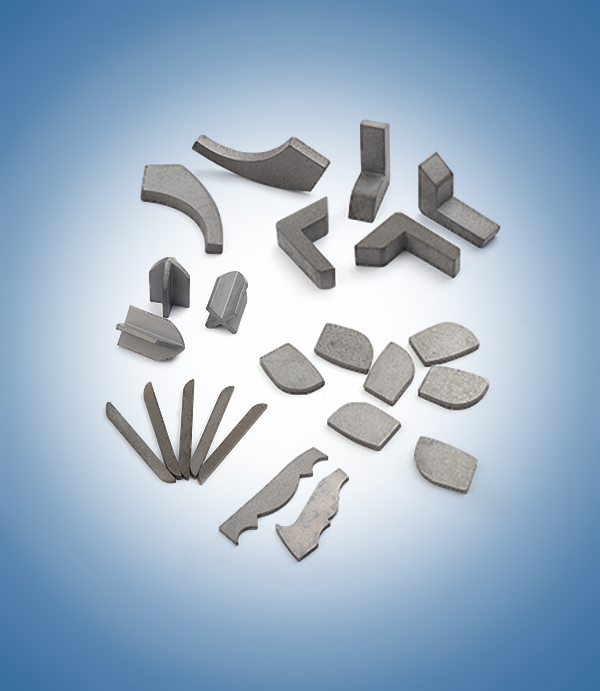

In the realm of metal cutting, the performance of a tool is fundamentally linked to the integrity of its manufacturing process. For end-users of indexable inserts and carbide welding blades, understanding how a specialized factory manages quality provides insight into product consistency and longevity. This article outlines the standard procedures an indexable insert factory employs to control the quality of carbide welding blades, ensuring they meet the demands of diverse machining applications.

The foundation of a durable carbide welding blade lies in the quality of the raw materials. Each batch of powder undergoes verification for grain size, purity, and composition. This step is critical, as the properties of the carbide substrate—its hardness, toughness, and wear resistance—are determined at this stage. A defined material specification ensures the final product is suited for its intended application, whether for machining ferrous materials like cast iron or for non-ferrous metals requiring a specific edge behavior.

The bonding of the carbide tip to the steel shank is a delicate operation. Factories control this through automated or semi-automated brazing systems. Key parameters such as brazing temperature, heating cycle duration, and the composition of the brazing filler alloy are tightly regulated. Precise temperature control prevents thermal stress cracks in the carbide, while the correct amount and placement of filler material ensure a void-free, robust joint. The goal is to achieve a metallurgical bond that maintains strength under the thermal and mechanical loads experienced during cutting, directly influencing the tool's service life and preventing premature failure.

After welding, each blade undergoes inspection for geometric accuracy. This involves measuring critical dimensions like length, width, thickness, and the positioning of the carbide tip. Tools such as optical comparators or coordinate measuring machines (CMMs) are used to verify that the blade conforms to specified drawings. Consistent geometry is essential for predictable tool performance, correct assembly into toolholders, and achieving the intended cutting angles during use. Variations outside tolerance can result in poor machining finish, vibration, or accelerated wear.

The welding process induces internal stresses. To address this, factories implement controlled post-weld treatments. This often involves a stress-relief annealing process where blades are heated to a specific temperature and cooled under controlled conditions. This treatment stabilizes the structure of both the carbide and the steel, enhancing the blade's structural integrity and resistance to chipping or fracture during interrupted cuts or heavy machining operations.

Beyond dimensional checks, quality control includes functional testing. Sample blades from production batches are subjected to simulated or actual machining tests under controlled conditions. Technicians evaluate performance indicators such as flank wear, edge integrity, and surface finish on test workpieces. For a blade intended for milling cast iron, its resistance to abrasive wear is assessed; for one designed for finishing aluminum, its ability to maintain a sharp edge is verified. This practical validation links the controlled manufacturing process directly to real-world application results.

A systematic factory maintains full traceability. Each production batch is documented, recording material certificates, process parameters, and inspection results. This allows for tracking and analysis. If a field inquiry arises regarding a specific batch, the factory can review the complete production history to identify any deviations and implement corrective actions. This closed-loop system supports ongoing process stability and informed decision-making.

Quality control is not a static set of checks but a dynamic system. Factories employ Statistical Process Control (SPC) methods to monitor key production variables over time. By analyzing data trends from the brazing furnace temperatures, dimensional measurements, and test results, engineers can identify potential process drift before it cause non-conforming products. This proactive approach, coupled with regular calibration of all measurement and production equipment, forms the basis for sustained and consistent output.

For machinists and procurement specialists, selecting carbide welding blades from a factory with this multi-stage control system translates into a more predictable and stable machining process. It means that each blade offers a consistent starting point for tool setup and machining parameter selection, contributing to efficient material removal and planned tool life management. The emphasis on controlled processes, from material to validation, provides a solid foundation for meeting the challenges presented by modern manufacturing materials and schedules.