2025-12-26

Automation has become a common focus in modern manufacturing, especially in metal cutting and welding operations. Tools from an Indexable Insert Factory, when combined with a Carbide Welding Blade, provide practical ways to improve the consistency and predictability of automated machining processes. These components interact with CNC systems to support controlled cutting, reduce unplanned interruptions, and allow machines to operate in a more uniform and manageable manner. Understanding how these components function within automated systems can help operators plan and execute machining tasks more efficiently.

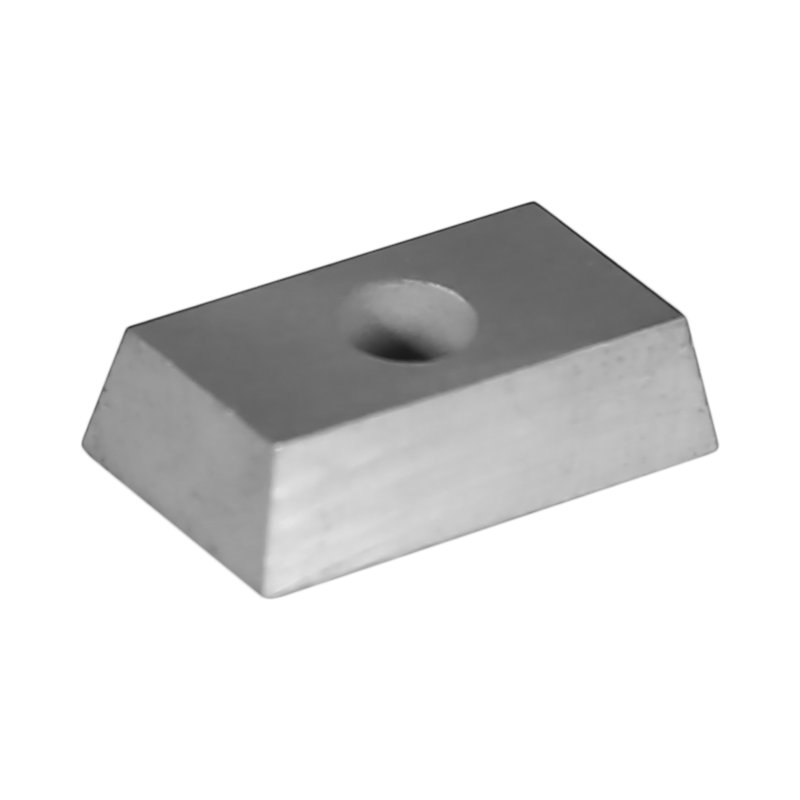

One of the primary benefits of using components from an indexable insert factory in automated operations is the consistency of tool geometry and placement. Indexable inserts are manufactured with uniform dimensions and tolerances, ensuring secure fitting into tool holders. When paired with carbide welding blades, this uniformity allows CNC systems to maintain stable engagement with the workpiece. Consistent tool contact reduces the need for frequent adjustments and helps maintain steady cutting forces, which supports smooth machine operation and reduces unplanned stops or slowdowns.

Automation relies on predictable interactions between tools and materials. Carbide welding blades maintain hardness and edge stability over repeated use, and indexable inserts contribute to reliable engagement with materials. Together, they allow machines to operate under controlled cutting conditions. Predictable cutting forces reduce variations in spindle load and vibration, which can otherwise disrupt automated sequences. This consistency supports efficient programming of CNC operations, allowing the system to follow planned paths without excessive intervention.

Frequent tool changes can interrupt automated production, requiring machine pauses and recalibration. Carbide welding blades, combined with durable indexable inserts, extend the operational period before replacements are necessary. Consistent insert performance ensures that each tool engages the workpiece predictably, which reduces errors that could necessitate early tool changes. By maintaining longer intervals between interventions, automated systems can maintain continuous operation with fewer interruptions, supporting smoother production cycles.

Automated systems benefit from tools that behave predictably under different operating conditions. Carbide welding blades resist edge wear and thermal deformation, while indexable inserts produced in controlled factory conditions maintain consistent cutting geometry. This combination allows machines to execute programmed operations without frequent manual adjustments. Operators can plan machining sequences with confidence that the tools will maintain the expected contact and pressure, supporting stable surface finish and dimensional accuracy in parts.

Modern CNC systems often include monitoring features that track load, vibration, and temperature during operations. Using indexable inserts alongside carbide welding blades provides consistent input for these monitoring systems. Because the tools maintain predictable performance, sensors can give accurate feedback on cutting conditions and help operators make informed adjustments. Stable tool behavior supports energy-efficient operation, as machines can maintain programmed speeds and feeds without overcompensating for irregular tool performance.

Different workpiece materials respond differently to cutting and welding processes. Carbide blades combined with properly selected indexable inserts can be adjusted to suit specific material characteristics. CNC programs can account for hardness, density, and thermal conductivity, while the tools provide consistent mechanical engagement. This alignment allows automated systems to operate within stable ranges of force and temperature, supporting predictable operation and reducing unplanned variations.

Using indexable inserts from specialized factories together with carbide welding blades offers several practical advantages for automation. Consistent tool geometry, predictable cutting forces, reduced tool change interruptions, and integration with CNC monitoring systems all contribute to more controlled and manageable automated machining. These components help maintain stability during production, support predictable material removal, and allow machines to follow programmed sequences with fewer adjustments, contributing to smoother and more efficient manufacturing operations.